In the realm of engineering, space is often a precious commodity. But fear not, for even when clearances are tight, a specialized hero emerges – the travelling nut screw jack. Let’s explore how these ingenious jacks conquer space limitations while delivering powerful linear actuation.

The Challenge: Lifting and Lowering in Confined Areas

- Limited Overhead Space: Traditional screw jacks, with their fixed screw shafts extending upwards, can be impractical in situations with limited overhead clearance. This poses a challenge for lifting or lowering objects in tight spaces.

- Restricted Access: Some applications might have limited access around the lifting point, making it difficult to accommodate the bulky rotating mechanism of a standard screw jack.

The Travelling Nut Screw Jack: A Design Innovation

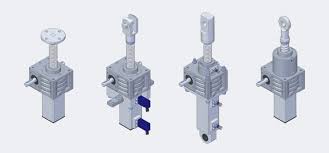

- Inverted Design: Unlike traditional jacks, the travelling nut screw jack flips the script. The lead screw (threaded shaft) remains stationary, while a nut containing the rotating mechanism travels up and down the screw, creating linear motion.

- Compact Footprint: This ingenious design eliminates the need for a rotating mechanism above the lifting point. The travelling nut itself houses the gearset, resulting in a more compact overall footprint.

Benefits for Space-Constrained Applications:

- Reduced Headroom Requirements: The travelling nut screw jack’s design significantly reduces the required overhead clearance compared to a traditional screw jack. This makes them ideal for situations with limited vertical space.

- Increased Design Flexibility: The compact footprint allows for greater flexibility in machine or equipment design. Travelling nut jacks can be integrated into tight spaces where traditional jacks might not fit.

- Simplified Integration: The travelling nut’s design often simplifies integration into existing structures or machinery due to the reduced need for additional space above the lifting point.

Applications for Tight Spaces:

- Machine Tooling: These jacks are valuable assets in machine tools with limited headroom, enabling precise tool positioning and adjustment within tight confines.

- Food and Beverage Processing Equipment: The compact design makes them suitable for lifting and lowering components within space-constrained food processing equipment.

- Packaging Machinery: Travelling nut screw jacks can be employed in packaging machinery for precise product handling and manipulation in areas with limited overhead space.

- Medical Equipment: Certain medical equipment, like X-ray machines, might benefit from the space-saving design of travelling nut jacks for patient positioning or component adjustment.

Additional Considerations:

- Load Capacity: Travelling nut screw jacks come in various load capacities to suit diverse applications. Selecting the right jack for the intended weight is crucial.

- Travel Length: The available travel length (lifting distance) of the travelling nut jack needs to match the application’s requirements.

- Environmental Factors: Choose jacks suitable for the operating environment, considering factors like dust, moisture, or washdown requirements.

Conclusion:

Travelling nut screw jacks are a testament to ingenious design. By conquering space constraints, they empower engineers to achieve powerful linear actuation even in the tightest spots. So, next time you face a space challenge, consider the travelling nut screw jack – the compact hero ready to tackle your lifting and lowering needs in confined environments.