There are various kinds of screw jacks available to convert rotary motion into linear travel, so selecting the best type for your application is essential.

Selecting an appropriate jack depends on its load capacity and duty cycle requirements, so once you understand this aspect of the selection process it should become much simpler to choose an actuator and other components suitable for your application.

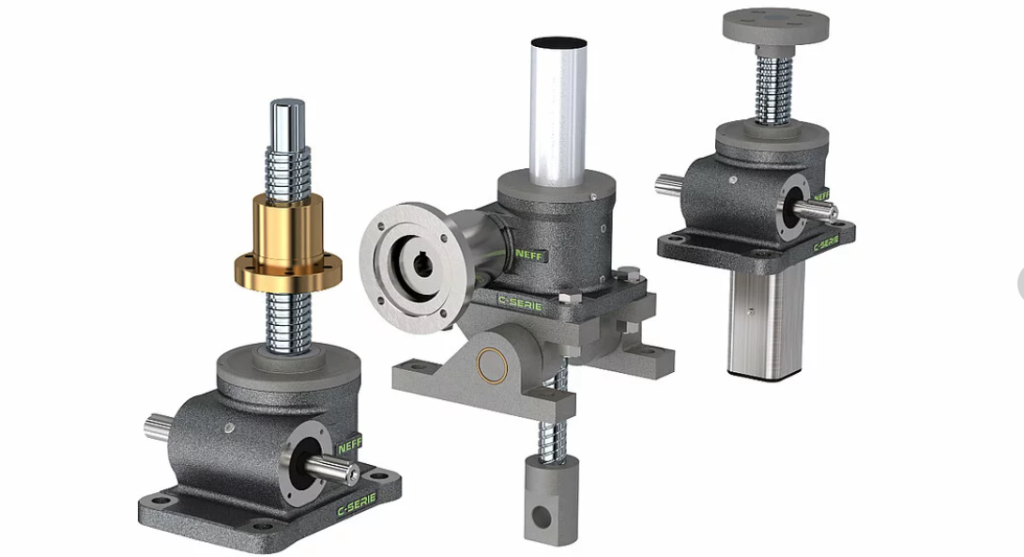

Trapezoidal Screw Jacks

Trapezoidal Screw Jacks can be used to raise, lower, align and move any type of load. They can be utilized individually or collectively when connected with shaft joints, bevel gearboxes or other transmission devices.

Trapezoidal screw jacks differ from traditional screw jacks in that they are irreversible and can support their loads without needing brakes or other locking mechanisms. They can be driven by various motors including electrical, alternating current direct current motors hydraulic pneumatic as well as manual operation.

There is a selection of thread profiles available in either inch or metric sizes. They can also be equipped with dustproof bellows and limit switches for control purposes.

Screw jacks are driven by a lead screw (also referred to as power screw), which travels up and down whenever the input shaft rotates either in one direction or the other. Three types of screw jacks exist: translating, keyed and anti-rotation.

Work Screw Jacks

Work Screw Jacks are ideal machines to raise, position, align and secure loads. Due to their reliability and synchronization qualities – which may not be achievable using other handling methods like pneumatic or hydraulic systems – they find widespread application.

These types of jacks utilize either a machine cut lead screw or ball screw to transfer rotational energy into linear motion, with a worm wheel acting on either end to facilitate translation. A nut slides along with the screw when translating.

Screw jacks come in various configurations that offer positive mechanical movement, precise positioning and smooth lifting speeds. Furthermore, these types of jacks also have self-locking mechanisms to keep loads steady without them moving backwards.

Anode Jacks

Anode Jacks can be utilized in numerous applications to raise or lower an anode beam in an electrolyte bath containing raw materials for smelting as well as chemical additives needed to facilitate this process. They use highly sophisticated electronic controls designed by experts in smelting systems to accomplish this feat.

Power Jacks, a British design and manufacturing company specializing in electro-mechanical lifting equipment. Offering both standard screw jacks as well as customized designs.

Our E-Series screw jacks offer precision worm gear sets, powerful lead screws, robust housing design and two integrated lubrication systems as standard features, plus an extensive variety of options.

Smelters face daily challenges to maximize efficiency and potline uptime while dealing with constant wear-and-tear on their equipment (24/7). Anode Jacks play an essential part of these systems.

Powered/Motorized Jacks

A Powered/Motorized Screw Jack is an electrically powered jack used to move and support loads, such as lifting and lowering automobiles from surfaces. Screw Jack Types have many uses such as lifting cars onto or off of them.

Engineers and mechanics use screw jacks to lift, position (by pushing, pulling, tilting or rolling), support all types of loads, and drive these systems with electric, AC/DC hydraulic or pneumatic motors.

Summary: Motorized/Powered Screwjacks are essential components of many machinery and equipment, transforming rotary motion into linear movement and force. Screw jacks typically consist of gearbox assemblies (either worm gear or bevel gear) and transmission products such as lead screw, ball screw or roller screw that can be driven by electric, AC/DC, hydraulic or pneumatic motors.

Manual screwjacks can often be frustrating and difficult for the average person to use, while motorized versions offer convenient operation with less physical strain required for operation. Motorized screw jacks can especially prove helpful at auto repair shops where raising and lowering vehicles is a frequent need.